Servo Drive

Injection Servo

Whether it is a new machine or a retrofit on an existing power guzzling machine, the Smart Servo Pump can offer you benefits that will reduce your operating cost. They are suitable for hydraulix metal forming presses, plastic injection and blow mouIding machines and any equipment that uses hydraulic power.

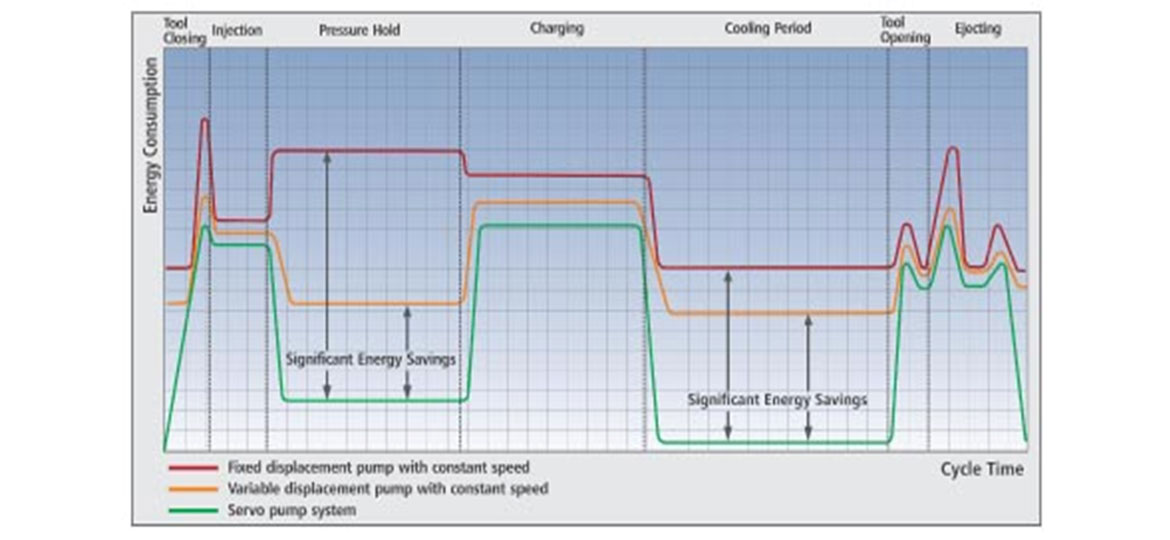

High dynamic changes of energy flow to individual hydraulic loads are typical for injection mouIding machines during the production cycle. Conventional hydraulic systems using fixed displacement pumps provide constant energy since the pump is running at fuII rpm at all times. This system is energy inefficient since power is wasted even when the machine is idIe or in no—load condition. This does not comply with the requirements of modern maChines wh ich demand high energy efficiencies and savings.

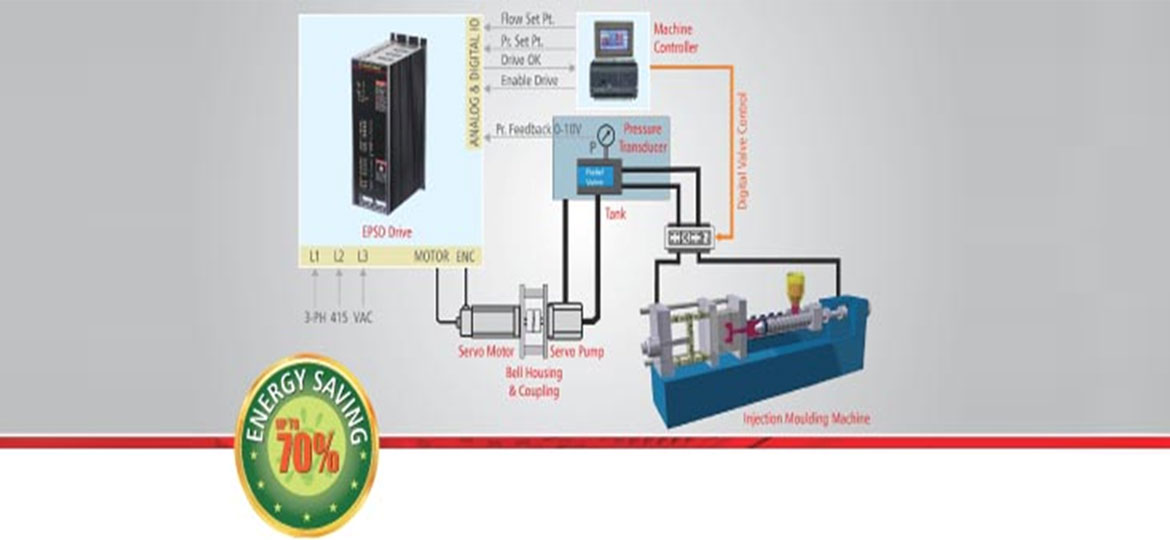

The solution is a “Smart Servo Pump” system. The existing hydraulix pump-motor assembly and proportional valves are replaced with a high dynamic performance servo pump and servo drive system. It is a synergy of advanced hydrau tics and intelligent drive systems. The smart servo pump supplies energy onIy on demand and consumes zero energy during idIe states. The performances are comparable to all-electric machines providing high dynamic response, yet energy efficient with smoother machine operation.

Benefits:

• Energy savings up to 70%, depending on the type of application

• Reduced noise levels and smoother machine operation

• Built—in closed loop PQ control in the servo drive replacing proportional valves. No additional PLC required.

• Reduced maintenance due to reduction in hydraulic elements.

• Considerable reduction in oil heating, up to 70% depending on the application.

• Detailed diagnosis using online monitoring software on PC/laptop or optional HMI.

• Cleaner working environment.